Micro-processor Based Bag Filter Controller

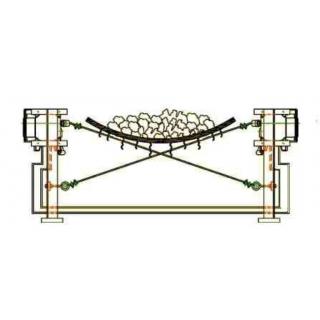

Description

Function:

Microprocessor / Microcontroller based Bag Filter Timer controls the cleaning cycle of Pulse Jet Bag Filter. This Timer is fully Programmable and has Digital Display to indicate all programming & Operating parameters.

It can be used for On-Line as well as Off-Line cleaning. Different application specific models are available to cater Off-Line Cleaning, On-Line Cleaning with Off Line feature, Solenoid Fault detection, Multiple configurable Timers in one unit, Master Controller & Slave timer application, MODBUS / PROFIBUS connectivity etc.

| MICROPROCESSOR BASED TIMER FAMILY |

| Series | Description | Output | Standard Outputs |

|---|---|---|---|

| MBFC Application: ON-Line cleaning |

Micro-processor Based Bag Filter Controller Timer with Digital Display, fully programmable | Relay | 10 & 16 channels Expandable up to 208 outputs |

| MBFC-SVF Application: ON-Line cleaning |

Micro-processor Based Bag Filter Controller with Digital Display and with Solenoid Open & Solenoid Short detection, Indication & Fault feedback facility. Also provides Timer Working Hour Meter & actual pulsing count per hour for estimating Bag Filter performance & compressed air consumption. | Relay | 10 & 16 channels Expandable up to 144 outputs |

| MBFC-ONL Application: ON-Line cleaning with Compartment Isolation facility or ON Line Cleaning with OFF Line feature |

Micro-processor Based Bag Filter Controller with Digital Display having Compartment isolation facility for maintenance purpose. The Pulse Valves in the isolated compartment become automatically in-operative when isolated.) | Relay | Available up to 208 Channels divided into maximum 16 Compartments Outputs divided into Compartment Valve (C.V) outputs & Pulse Valve (P.V.) outputs. Output Channels = (C.V. + C.V. X P.V.) |

| MBFC-PLNM Application: OFF-Line cleaning Compartment isolation feedback optional |

Micro-processor Based Bag Filter Controller with Digital Display. One by one Compartment are isolated by closing its inlet / outlet Dampers (to make it OFF Line) & purging is done only in isolated compartment. | Relay | Available 208 Channels divided into 16 Compartments (Max.) Outputs divided into Compartment Valve (C.V) outputs & Pulse Valve (P.V.) outputs. Output Channels = (C.V. + C.V. X P.V.) |

| MBFC-xG Application: ON-Line cleaning with Channel Grouping facility |

Micro-processor Based Bag Filter Controller with digital display. Maximum 4 Groups can be programmed. Each Group works as an independent Timer. Output channel grouping is flexible. Only input interlocks are common. Suitable for Roots Blower Application also. | Relay | Up to 96 Channels. Channel grouping is fully flexible. |

| MBFC-BFC Application: ON Line or OFF Line Cleaning for Process Bag filters. On Line / Off Line cleaning is programmable at site. |

Master Controller (with Digital display) and Slave Timer combination. Suitable for 2 to 16 Compartments and outputs up to 1536. Here Master Controller can be placed at central location and slave timers at the Bag Filter top near solenoid coils. The communication between Master Controller and Slave Timer is through 110V / 230 Vac potential signals. Hence no drop of signal due to cable length. This model reduces expenses on cabling. | Relay | Up to 1536 Channels divided into 16 Compartments. Outputs divided into Compartment Valve (C.V) outputs & Pulse Valve (P.V.) outputs. Output Channels = (C.V. + C.V. X P.V.) |

| MBFC-RABH Application: ON-Line cleaning with Channel Grouping facility |

Micro-processor Based Bag Filter Controller with Digital Display | Relay | For Compartments up to: 16 Nos. Inlet Valve, Outlet Valve & Damper Outlets are controlled. |

| MBFC-SILO Application: Silo Aeration |

Micro-processor Timer with Digital Display. A Here ON time of successive compartments is overlapping on each other. There is no OFF Time. | Relay | Up to 16 outputs. |

| MBFC-SVF-BLD Application: ON-Line cleaning |

Micro-processor Based Bag Filter Controller with Digital Display and with Solenoid Open & Solenoid Short detection, Indication & Fault feedback facility. Optionally it can accept 4-20mA input from Bag Leak Detector and displays exact Leaked Bag channel number. Similarly faulty channel get skipped automatically. Also provides Timer Working Hour Meter & actual pulsing count per hour for estimating Bag Filter performance & compressed air consumption. | Up to 96 outputs. |

For detailed technical specifications contact us

Microcontroller based Bag Filter Timers are used in De-Dusting and Process Bag House in various industries such as: Aluminum, Asbestos, Carbon Black, Clay, Detergent, Gypsum, Limestone, Saw Dust, Steel / Sponge Iron, Solvent Extraction, Non-ferrous, Bagasse Dust, Cement, Food Grain Handling, Fly Ash, Iron Ore, Sugar, Chemicals, Fertilizers, Flour, Tea, Ceramic, Coal, Paint Pigments, Milk Powder, Soda Ash, Battery Industries, Wood, Spices etc.